Welding and Grinding

Welding is carried out by professionally qualified and experienced welders, and the Trumpf TruLaser Weld 5000 laser welding machine allows us to assemble all the elements into a finished product, which is then treated by grinding. Grinding removes excess residues and imperfections from the product and ensures a professional and sophisticated final appearance.

LASER WELDING

Using our Trumpf robotic laser welding machine, we can achieve the highest quality welds. Depending on the requirements, completely new weld geometries are possible, achieved without or with the use of material addition. High welding speed and high quality and appearance of the weld are achieved, so in most cases no grinding or polishing is required.

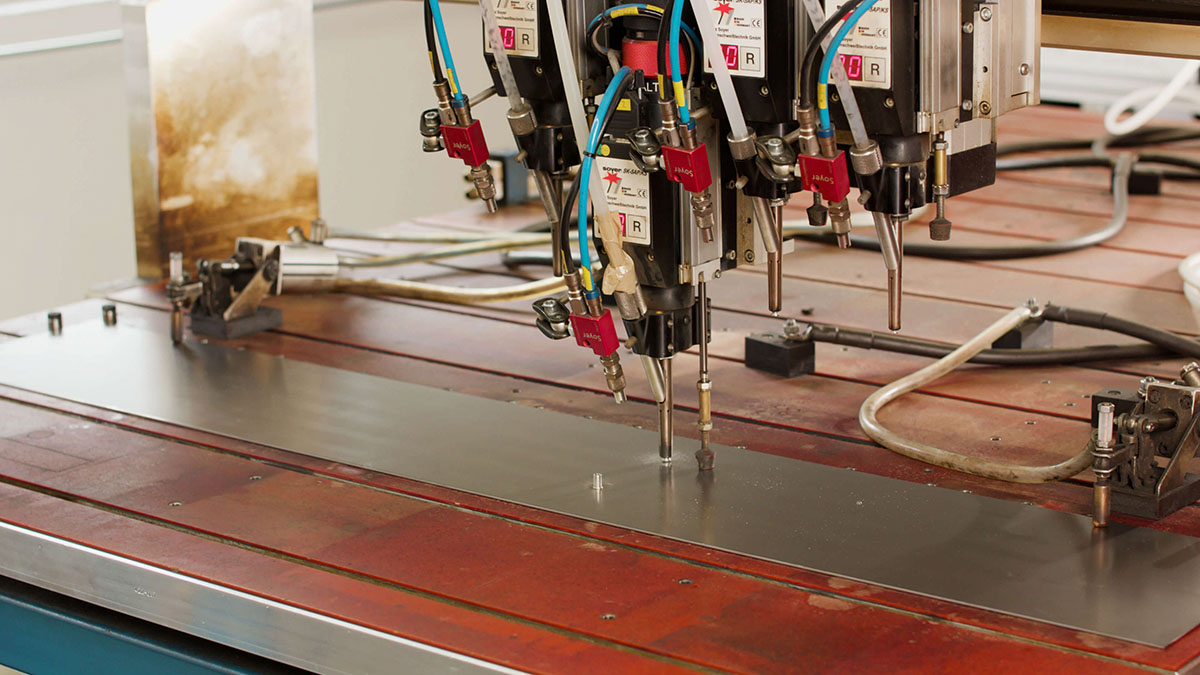

CAPACITOR DISCHARGE WELDING

RESISTANCE WELDING

Spot welding of two steel weldments using the electric current. In spot welding, two oppositely positioned copper electrodes are pressed together and the electric current is directed to a small point, welding the piece in 10–100 milliseconds. The thickness of the material suitable for welding ranges from 0.5 to 3 mm.

GRINDING AND DEBURRING

By grinding the product, we remove excess residues and imperfections and ensure the design and a professional and sophisticated final appearance of the product. We offer both machine rust removal and manual grinding of the product.